National Hotline

+86 400 888 9412

Consult Now

Consult Now

Robostar focuses on providing positive and negative electrode slurry transportation solutions for lithium battery raw material production enterprises. We have a professional R&D and technical team, as well as strong support from our headquarters in the United States. We specialize in tailoring personalized scientific solutions for our customers, creating a safe, secure, and worry free user experience.

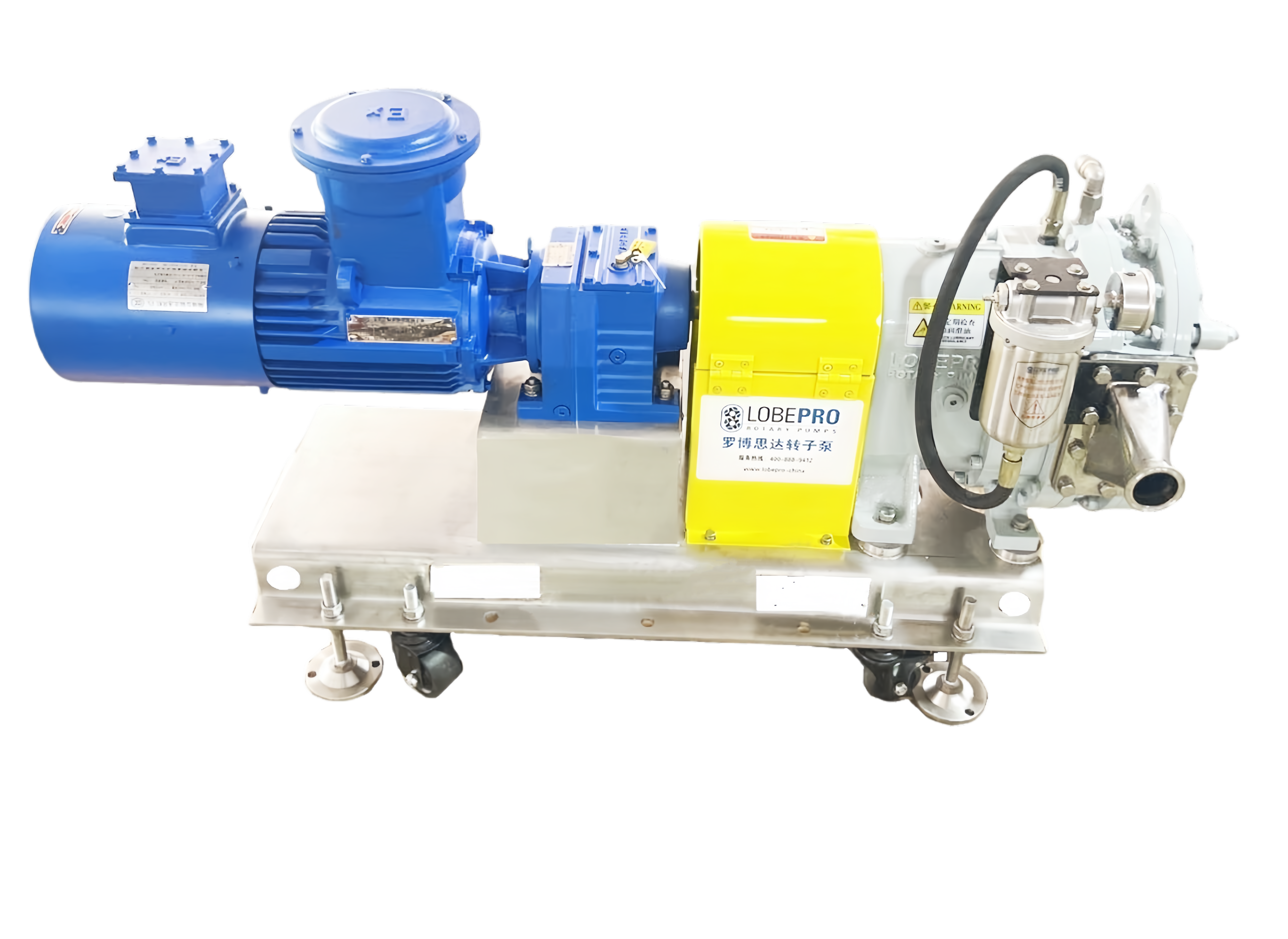

The Rotary Lobe pump, designed with the latest technology, is a rotary volumetric pump for conveying lithium battery slurry. It has a set of synchronous and reverse rotating rotors that gradually increase the volume of the inlet chamber to form negative pressure during rotation, thereby sucking in the material to be conveyed and forming sealed chambers. The material is continuously sucked into the pump chamber, gradually forming pressure, pushing the material towards the pump chamber and discharging the conveying medium out of the pump chamber.

Our rotary pump flow rate and speed are linear, and adjusting the speed can adjust the pump flow rate. Therefore, it is widely used in quantitative conveying and metering, various wear fluid medium conveying, and vacuum suction and conveying conditions.

The advantages include advanced working principle, easy maintenance, stable performance, excellent quality, low maintenance cost, safety and reliability, and elimination of material leakage.

LobePro rotary pump has the following 6 technical advantages:

1. Four major series with 50 specifications, flow range 0-1,500m3/h;

2. Lithium ion specific EPDM rubber rotor, metal rotor, ceramic rotor;

3. Unique adjustable pump casing technology, no need to replace spare parts after wear, adjust the clearance between the pump casing and rotor to restore performance; Repeat 2-3 times before replacement to avoid the risk of downtime for repair or production stoppage;

4. The pump casing is made of stainless steel or duplex stainless steel material, and can also be lined with replaceable ceramic protective liners to extend its lifespan by 3-5 times;

5. The invention patent technology container machine seal (invention patent number: ZL.2011 8 0049959.9) is designed for harsh working conditions, with a lifespan 2-3 times that of traditional machine seals, especially suitable for media with high viscosity and high solid content;

6. Online maintenance design, saving 70% of spare parts compared to the same period last year; Greatly save maintenance costs.

Lithium battery slurry conveying rotary pump, replaces domestic rotary pumps and imported diaphragm pumps